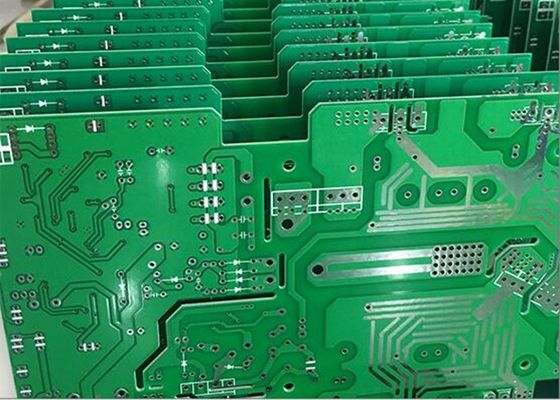

Single side PCBs

Double sided PCBs

Multi-layer PCBs

All of the other electronic components are mounted on the printed circuit boards(PCBs),which are the foundation.

PCBs have mechanical and electrical attributes,making them for ideal applications. Most PCB’s fabricated are rigid, roughly 90% of the PCB’s manufactured today are rigid boards.

| Quality Grade | Standard IPC 2 | Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI |

| Number of Layers | 1 - 8layers | Board Size | Custom |

| Order Quantity | 1pc - 10000+pcs | Board Thickness | 0.1mm - 0.8mm |

| Build Time | 2days - 5weeks | Copper Weight (Finished) | 0.5oz - 6.0oz |

| Min Tracing/Spacing | 3mil/3mil | Silkscreen Sides | As per the file |

| Solder Mask Sides | As per the file | Silkscreen Color | White, Black, Yellow |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | Surface Finish | HASL - Hot air solder leveling |

| Solder-stop coating---Soldermask oil | Green, White, Blue, Black, Red, Yellow | Lead - free HASL - RoHS | |

| Solder-stop coating---Coverlay | PI and PET film | ENIG - RoHS | |

| Min Annular Ring | 3mil | Immersion Tin - RoHS | |

| Min Drilling Hole Diameter | 8mil | OSP - RoHS | |

| Min. hole size---Drilling (PTH) | 0.2mil | Other Techniques | Peelable solder mask ;Gold fingers ;Stiffener (only for PI/FR4 substrate) |

PCB Assembly Process

![]()

![]()

![]()

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Our products are widely used in communication equipment, industrial control, consumer electronics, medical equipment, aerospace, light-emitting diode lighting, automotive electronics etc.

![]()

Workshop

![]()

![]()

![]()

1.PCB: Vacuum packaging with carton box

2.PCBA: ESD packaging with carton box

![]()

FAQ

Q1: What service do you have?

A1: We provide turnkey solution including RD, PCB fabrication, SMT, final assembly ,testing and other

value-added service.

Q2: What are the main products of your PCB/PCBA services?

A2: Our PCB/PCBA services are mainly for the industries including Medical, Automotive, Energy,

Metering/Measurements, Consumer Electronics.

Q3: Can we inspect quality during production?

A3: Yes, we are open and transparent on each production process with nothing to hide. We welcome customer

inspect our production process and check in house

Q4: How can we ensure our information should not let third party to see our design?

A4: We can sign NDA effect by customer side local law and promising to keep customers data in high

confidential level.

Q5: What does customer need for a customized PCB order?

A5: When you place a PCB order, the customers need to provide Gerber or pcb file. If you do not have the file in

the correct fomat, you can send all the details related to the products.

Q7: Does you have an minimum order quantity?

A7: We accept order with as low as a quantity of 1 (piece or panel).

Q8:what is the difference between PCB, PCBA and FPC?

A8: PCB is bare board without any components.

PCBA is the PCB through SMT or plug-in processing, welding assembly on the PCB board required electronic components, such as IC, resistor, capacitor, crystal oscillator, transformer and other electronic components, after reflow oven high temperature heating, will form the mechanical connection between components and PCB board, thus forming PCBA.

FPC generally uses Pi as base material, which is flexible and can be bent and flexed at will .