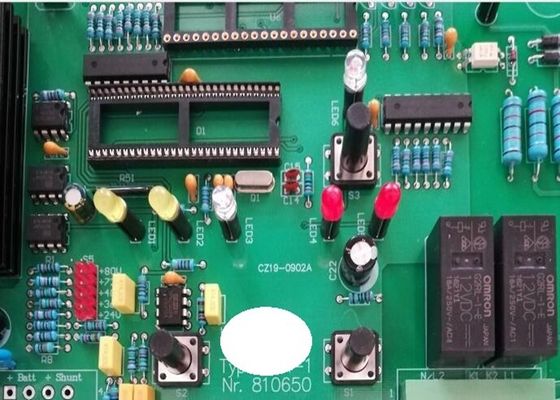

The double-sided printed circuit board (also double-layer board)provides on both side conductive paths for assembly of components, then to fabricate the PCB'A.

Haina Lean Electronics is providing high quality bare PCB,PCB layout design service and PCB assembly service,including components sourcing, function test,conformal coating and complete assembly for clients all.

Producing surface-mount (SMT), through-hole (THT) and mixed-technology components and fine-pitch parts and ball grid arrays (BGAs) for high-density FR-4 PCBs .

| Base material | FR4,High-TG FR4,CEM3,aluminum, High frequency(Rogers,Taconic,Aron,PTFE,) |

| Layers | 1-46 |

| Copper Thickness | 0.3oz,0.5oz, 1oz, 2oz, 3oz,4oz,5oz, 6oz |

| Dielectric Thickness | 0.05mm, 0.075mm, 0.1mm,0.15mm,0.2mm |

| board Core Thickness | 0.4mm,0.6mm, 0.8mm, 1.0mm, 1.2mm, |

| 1.5mm, 2.0mm, 3.0mm and 3.2mm | |

| Board Thickness | 0.3mm - 4.0mm |

| Thickness Tolerance | +/-10% |

| Surface Finishing | HASL lead free,ENIG,Plated Gold,Immersion Gold,OSP |

| Solder Mask Color | Green, Blue, Black, White, Yellow, Red, Matt Green, Matt Black, Matt Blue |

| Legend Color | Black, White etc |

| Assembly Types | Surface mount |

| Thro-hole | |

| Mixed technology (SMT & Thru-hole) | |

| Single or double sided placement | |

| Conformal coating | |

| Shield cover assembly for EMI emission control | |

| Parts Procurement | Full Turnkey, Partial Turnkey, Kitted / Consigned |

| Component types | SMT 01005 or larger |

| BGA 0.4mm pitch, POP (Package on Package) | |

| WLCSP 0.35mm pitch | |

| Hard metric connectors | |

| Cable & wire | |

| Other Techniques | Free DFM Review |

| Box Build Assembly | |

| 100% AOI test and X-ray test for BGA | |

| Components cost-down | |

| Function test as custom | |

| Protection technology |

Our SMT capabilities:

SMT Assembly: SMT provides a flexible high technology. These solutions include:

7 high-speed placement machines,

7 automatic printers with fiducial alignment,

2 X-ray machines,

BGA maintenance machines,

ICT test machines

Our DIP function:

A-8 semi-assembly production line with four wave soldering machines

1 U-shaped automatic assembly line for box-type building products with test stations

High temperature / low temperature aging test furnace B-4 for products required for aging test

With time control and temperature control

All products are 100% inspected and tested during the DIP process

Haina lean Electronics Co.,Ltd is a competitive China customize pcba for medical breathing machine OEM manufacturer, supplier and vendor, you can get quick turn customize pcba for medical breathing machine production prototypes and samples from our factory.

Hot Tags: customize pcba for medical breathing machine, China, supplier, manufacturer, factory, OEM manufacturer, vendor, samples, production, prototypes, quick turn

Double Side PCB Assembly Process

![]()

1.Service value

Independent quotation system to quickly serve the market

2.PCB manufacturing

High-tech PCB and PCB assembly production line

3.Material purchasing

A team of experienced electronic component procurement engineers

4.SMT post soldering

Dust-free workshop, high-end SMT patch processing

![]()

![]()

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Our products are widely used in the following areas:

1. communication equipment,

2. industrial control,

3.consumer electronics,

4.medical equipment,

5. aerospace,

6.light-emitting diode lighting,

7.automotive electronics etc

![]()

Workshop

![]()

![]()

![]()

![]()

1.PCB: Vacuum packaging with carton box

2.PCBA: ESD packaging with carton box

![]()

FAQ:

Q1:What service do you have?

A1: We provide turnkey solution including RD, PCB fabrication, SMT, final assembly,testing and other

value-added service.

Q2:What are the main products of your PCB/PCBA services?

A2:Our PCB/PCBA services are mainly for the industries including Medical, Automotive, Energy,

Metering/Measurements. Consumer Electronics.

Q3:How can we ensure our information should not let third party to see our design?

A3: We are wiling to sign NDA effect by customer side locallaw and promising to keep customers datain highconfidential level.

Q4:What does Parason need for a customized PCB order?

A4:When you place a PCB order, the customers need to provide Gerber or pcb file.If you do not have the fileinthe correct format, you can send all the details related to the products.

Q5:What will be needed for a customized PCBA order?

A5: When you place a PCBA order, you need to provide Gerber or pcb file and the BOM list to us.

Q6:Do you have an minimum order quantity?

A6:We accept order with as low as a quantity of 1 (piece or panel)