-

High Light

High Tg Lead Free PCB Assembly

,FR-4 Lead Free PCB Assembly

,Lead Free PCBA Main Board

-

Product NameLead Free PCB Assembly

-

Layers1-36layers

-

Copper Thickness0.3oz-6oz

-

Min. Line Spacing0.030mm/0.030mm

-

Board Thickness0.3-3.5mm

-

Min. Hole SizeLaser 0.05mm ; Mechnical 0.15

-

MaterialFR-4/Normal Tg/High Tg/Low Dk/HF FR4/ Aluminium

-

Surface FinishingHASL,OSP,ENIG,HASL Lead Free,Immersion Gold

-

Solder Mask ColorGreen, Yellow, Red, Black, Blue, Whiteetc

-

ApplicationTelecom Communication ;Military ; Automotive Industry ;Industrial Control ;Consumer Electronics Office Equipment;Household ;Aerospace; Elevator; High Speed Railway.

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A ,QC080000

-

Model NumberPCB Assembly

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

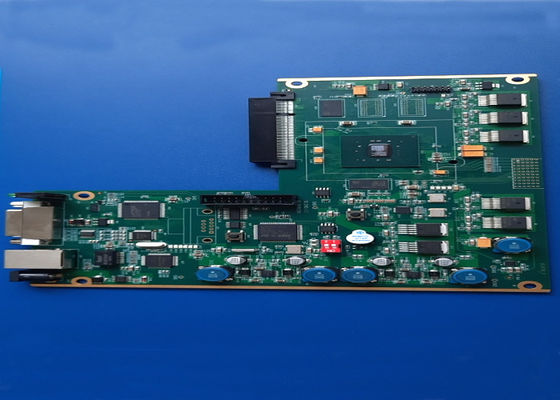

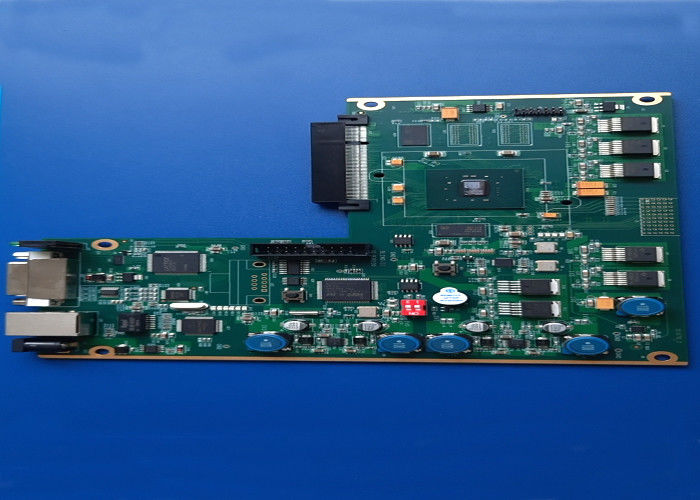

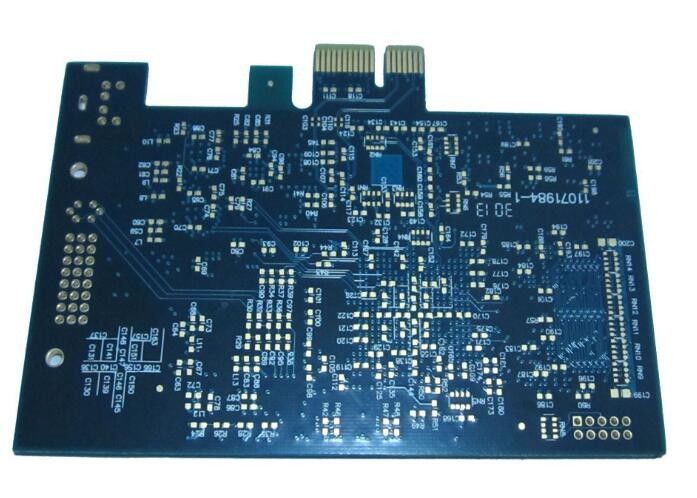

High Tg FR-4 Conformal Coating Lead Free PCB Assembly

High Tg FR-4 Conformal coating Lead Free PCB Assembly

PCB Assembly Introduction

PCBA refers to the complete electronic circuit board after all components have been assembled . It has many benefits that make it a much sought-after element in the communicating and electronics industry.

The PCBA is a complete assembly. You have to assemble the PCB, once it is ready. The assembling requires both passive and active components. The list of these electronic components include-

Resistor

SMD capacitor

Transformer

Diode

ICs

Transmitter

The PCBA electronic components have two types.

1. SMD components

2. Through-hole components

Factory Capabilities

| PCB Assembly Capability | ||

| Item | Capability | |

| Advantages | Professional Surface-mounting and Through-hole soldering technology | |

| Various sizes like 1206,0805,0603 components SMT technology | ||

| ICT(In Circuit Test),FCT(Functional Circuit Test) | ||

| PCB Assembly With UL,ISODD,Rohs Approval | ||

| SMT process adpot reflow soldering technology | ||

| High Standard SMT & Solder Assembly Line | ||

| HDI technology (High density interconnected board placement technology capacity) | ||

| Components | Chip & IC 01005 ,55mm | |

| BGA pitch 0.3mm | ||

| QFP Pitch 0.3mm | ||

| Quantity | Prototype & Low Volume PCB Assembly,from 1 Board to 250, or up to 5000 and customized | |

| Type of Assembly | SMT, Thru-hole ,DIP ,MIX | |

| Solder Type | Water Soluble Solder Paste, Leaded and Lead-Free | |

| Bare Board Size | Largest:700X610mm (Custom) | |

| File Formate | Gerber files, Pick-N-Place file, BOM ,PADs ,Protel,CAD | |

| Types of Service | Turn-key,partial turn-key or consignment | |

| Testing | Flying Probe Test,X-ray Inspection AOI Test | |

| PCB assembly process | Drilling----Exposure-----Plating-----Etaching & Stripping---Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling---- ICT-----Function Testing-----Temperature & Humidity Testing | |

Lead free PCB Aassembly Production Process

PCB,Component sourcing ,QC ,SMT Process ,AOI ,Test ,Automatic optical inspection ,DIP Process ,Washing board ,FQC .

![]()

Our WorkShop

![]()

Products Show

![]()

PCB Assembly Application Field

Aerospace ; Telecom Communication ;Automotive Industry ;Industrial Control ;Consumer Electronics ,etc.

![]()

Delivery Time

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Partners

![]()

Common packaging

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

![]()

FAQ

Q1:What kind of PCB file format can you accept for production?

Gerber, PROTEL 99SE, PROTEL DXP, CAM350, ODB+(.TGZ)

Q2:Is my PCB files safe when I submit them to you for manufacturing?

We respect customer's copyright and will never manufacture PCB for someone else with your files unless we receive written permission from you, nor we'll share these files with any other 3rd parties.

Q3:What payments do you accept ?

-Telex Transfer(T/T),Western Union,Letter of Credit(L/C)

-Paypal,AliPay,Credit Card

Q4:How to get the PCB?

A:For small packages, we will ship the boards to you by DHL,UPS,FedEx,EMS. Door to door service! You will get your PCBs at your home.

B:For heavy goods more than 300kg, we may ship your boards by ship or by air to save freight cost. Of course, if you have your own forwarder, we may contact them for dealing with your shipment.

Q5:What is your minimum order quantity?

Our MOQ is 1 PCS.

Q6: Can we visit your company?

No problem. You are welcome to visit us in Beijing. Or the branch factory is in Tianjin.

Q7: How can you ensure the quality of the PCB?

Our PCBs are 100% test including Flying Probe Test, E-test and AOI.