-

High Light

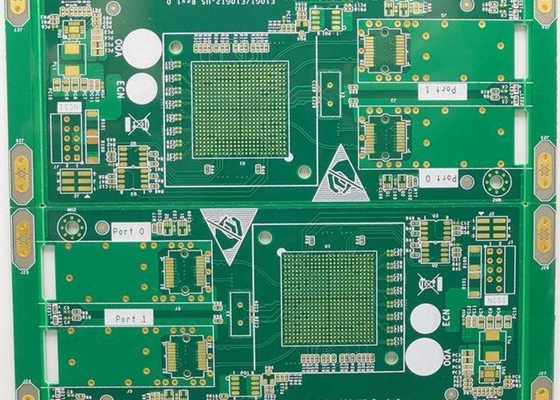

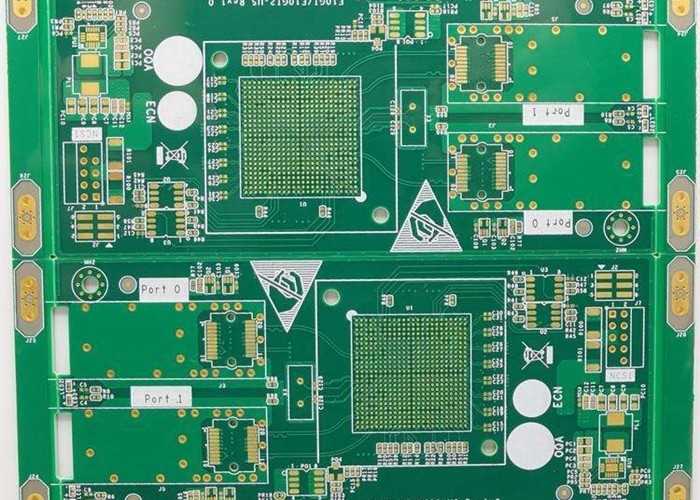

green hdi pcb board

,high end hdi pcb board

,automotive electronics hdi circuit boards

-

Product NameGreen High-End HDI Printed Circuit Board For Automotive Electronics

-

MaterialFR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI

-

Copper Thickness1oz ,2oz ...6oz

-

Min. Line Spacing0.030mm,0.05mm

-

Min. Hole Size0.05mm, 0.1mm, 0.25mm, 0.1mm/4mil, 4mil, 0.02

-

UsageMobile Phones, Digital (camera) Cameras, Notebook Computers, Automotive Electronics And Other Digital Products,

-

Board Thickness0.3mm,,,1.6mm,,,3.5mm

-

Solder MaskGreen. Black. Red. Yellow. White. Blue Etc.; Custom

-

TypeBuried Vias And Through Vias

-

Surface FinishingENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS , UL, IPC-A , UL, QC080000

-

Model NumberPCB Assembly 012

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

Green High End Hdi Pcb Board For Automotive Electronics

Green High-End HDI Printed Circuit Board For Automotive Electronics

HDI PCB Board Introduction

HDI is the abbreviation of High Density Interconnector, which is a (technology) for the production of printed circuit boards. HDI is a compact product designed for small volume users.

High Density Integration (HDI) technology enables more miniaturization of end product designs while meeting higher standards for electronic performance and efficiency. HDI is widely used in mobile phones, digital (camera) cameras, notebook computers, automotive electronics and other digital products, among which mobile phones are the most widely used. HDI boards are generally manufactured by the build-up method. Ordinary HDI boards are basically one-time buildup, and high-end HDI uses two or more buildup technologies, while using advanced PCB technologies such as stacking, electroplating, and laser direct drilling. High-end HDI boards are mainly used in mobile phones, advanced digital cameras, IC substrates, etc.

Advantages of HDI circuit

1. It can reduce the cost of PCB: when the density of the PCB increases beyond the eight-layer board, it is manufactured with HDI, and the cost will be lower than the traditional complex lamination process.

2. Increase line density: interconnection of traditional circuit boards and parts

3. Conducive to the use of advanced construction technology

4. Has better electrical performance and signal accuracy

5. Better reliability

6. Can improve thermal properties

7. Can improve radio frequency interference/electromagnetic wave interference/electrostatic discharge (RFI/EMI/ESD)

8. Increase design efficiency

PCB CAPABILITIES

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size | Laser 0.075mm | Laser 0.05mm |

| Mechnical 0.15mm | Mechnical 0.15mm | ||

| 5 | Min Line Width/Space | 0.035mm/0.035mm | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily Output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | ENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

The types of HDI PCB

1.through vias from surface to surface,

2.with buried vias and through vias,

3.two or more HDI layer with through vias,

4.passive substrate with no electrical connection,

5.coreless construction using layer pairs

6.alternate constructions of coreless constructions using layer pairs.

HDI (High Density Interconnection) circuit boards usually include laser blind vias and mechanical blind vias; general through buried vias, blind vias, stacked vias, staggered vias, cross blind buried, through vias, blind via filling plating, fine line small gaps, The technology of realizing the conduction between the inner and outer layers by processes such as micro-holes in the disk, usually the diameter of the blind buried is not more than 6 mils.

![]()

Work flow for HDI

Board Cut - Inner Wet film -DES - AOI - Brown Oxido - Outer Layer Press - Out Layer Lamination - X-RAY & Rounting - Copper reduce & brown oxide - Laser Drilling - Drilling - Desmear PTH - Panel plating - Outer Layer dry film - Etching - AOI- Impedance Testing - S/M Pluged hole - Solder Mask - Component Mark - Impedance testing - Immersion Gold -V-cut - Routing - Electrical Test - FQC - FQA -Package -Shipment

![]()

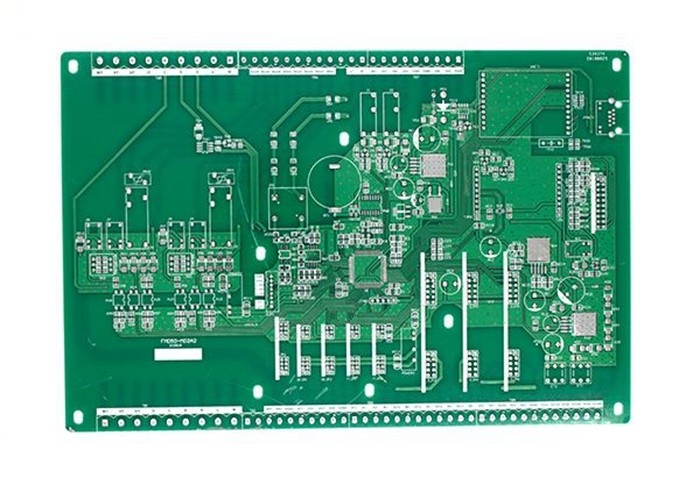

Similar products

![]()

HDI PCB Board Application Field

Our PCB are widely used in mobile phones, digital (camera) cameras, notebook computers, automotive electronics and other digital products, communication equipment, industrial control, consumer electronics, medical equipment, aerospace, light-emitting diode lighting, automotive electronics etc.

Workshop

![]()

![]()

![]()

Common packaging

1.PCB: Vacuum packaging with carton box

2.PCBA: ESD packaging with carton box

![]()

Our advantage

1.Service value

Independent quotation system to quickly serve the market

2.PCB manufacturing

High-tech PCB and PCB assembly production line

3.Material purchasing

A team of experienced electronic component procurement engineers

4.SMT post soldering

Dust-free workshop, high-end SMT patch processing

![]()