HF FR4 OSP 4 Layer Double Side PCB Assembly , 2oz Quick Turn PCB Assembly

-

High Light

HF FR4 OSP Double Side PCB Assembly

,4 Layer Double Side PCB Assembly

,2oz quick turn PCB assembly

-

Product NameQuick Turn Pcb Assembly

-

Number Of Layers1-36 Layers

-

Copper Thickness1/3oz-6oz

-

Min. Line Spacing0.030mm ,0.03mm

-

Board Thickness0.3mm-3.5mm

-

Min. Hole SizeLaser 0.05mm ; Mechnical 0.15

-

Solder Mask ColorBlue.green.red.black.white.etc

-

MaterialFR4 /Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI

-

Surface FinishingHASL Lead Free/ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD

-

ApplicationCommunication Equipment, Industrial Control, Consumer Electronics, Medical Equipment, Aerospace,ect.

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A , UL, QC080000

-

Model NumberDouble Side PCB Assembly

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

HF FR4 OSP 4 Layer Double Side PCB Assembly , 2oz Quick Turn PCB Assembly

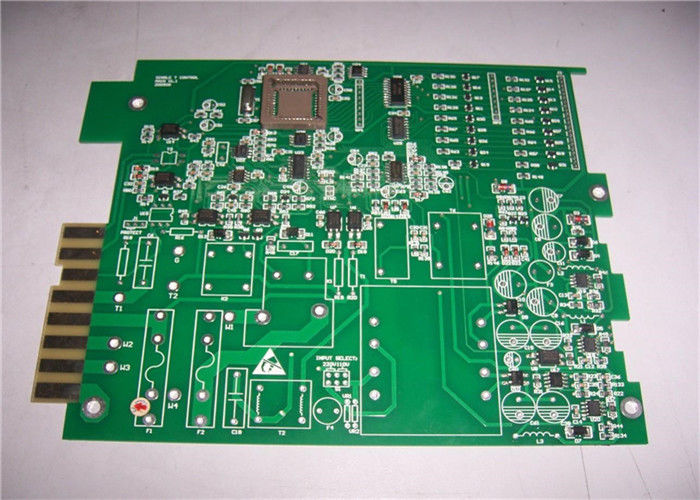

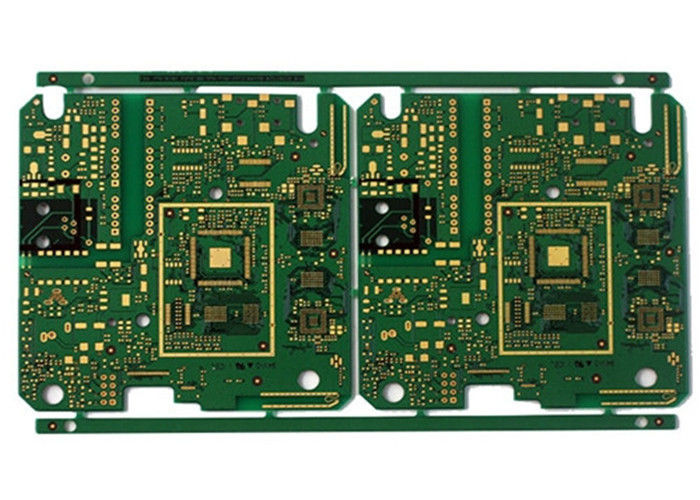

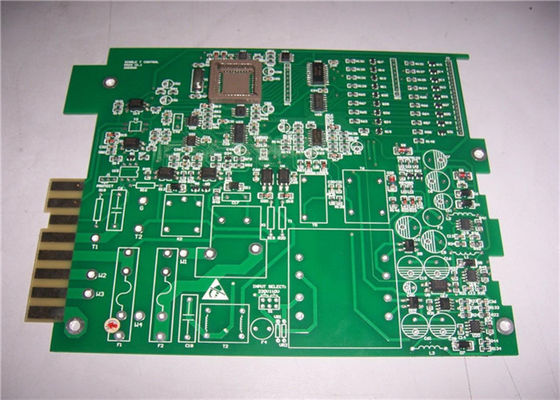

HF FR4 OSP 4 Layer Pcb Prototype Double Sided Circuit Board Quick Turn Pcb Assembly

PCB Assembly Introduction

Haina Lean Electronics is providing high quality bare PCB,PCB layout design service and PCB assembly service,including components sourcing, function test,conformal coating and complete assembly for clients all.

Producing surface-mount (SMT), through-hole (THT) and mixed-technology components and fine-pitch parts and ball grid arrays (BGAs) for high-density FR-4 PCBs .

The Double-sided circuit board assembly have copper tracking and component pads on the top and bottom side of the PCB board, and often each side is interlinked by through-hole vias. Double-sided assembly requires the placement of components on both sides of the PCB .

To populate the underside with surface mount components, the PCB is inverted and the pasting and component placement process simply repeated. The second pass through the reflow oven does not melt the previously soldered side, as the joints are protected from the direct heat by being on the underside of the assembly.

PCB CAPABILITIES

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size | Laser 0.075mm | Laser 0.05mm |

| Mechnical 0.15mm | Mechnical 0.15mm | ||

| 5 | Min Line Width/Space | 0.035mm/0.035mm | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily Output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | HASL lead free/ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

PCBA CAPABILITIES

| PCBA Capability | ||||||

| Material type | PCB | Components | ||||

| Item | Dimension (Length, width,height. mm) | Material | Surface finish | Chip&IC | BGA Pitch | QFP Pitch |

| Min | 50*40*0.38 | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | HASL, OSP, Immersion gold, Flash Gold Finger | 1005 | 0.3mm | 0.3mm |

| Max | 600*400*4.2 | |||||

Our SMT capabilities:

SMT Assembly: SMT provides a flexible high technology.

These solutions include:

7 high-speed placement machines,

7 automatic printers with fiducial alignment,

2 X-ray machines,

BGA maintenance machines,

ICT test machines

Our DIP function:

A-8 semi-assembly production line with four wave soldering machines

1 U-shaped automatic assembly line for box-type building products with test stations

High temperature / low temperature aging test furnace B-4 for products required for aging test

With time control and temperature control

All products are 100% inspected and tested during the DIP process

Haina lean Electronics Co.,Ltd is a competitive China customize pcba for medical breathing machine OEM manufacturer, supplier and vendor, you can get quick turn customize pcba for medical breathing machine production prototypes and samples from our factory.

Hot Tags: customize pcba for medical breathing machine, China, supplier, manufacturer, factory, OEM manufacturer, vendor, samples, production, prototypes, quick turn

Double Side PCB Assembly Process

1.Solder Paste stenciling---2.Surface Mount Technology (Pick and Place)---3.Reflow Soldering---4.Inspection and Quality Control---5.Through-Hole Component Insertion (DIP Process)---6.Final Inspection and Functional Test

![]()

Our advantage

1.Service value

Independent quotation system to quickly serve the market

2.PCB manufacturing

High-tech PCB and PCB assembly production line

3.Material purchasing

A team of experienced electronic component procurement engineers

4.SMT post soldering

Dust-free workshop, high-end SMT patch processing

![]()

Why choose us?

1. We are the manufacturer/ factory; Welcome to visit us one day.

2. We have good quality control systems, including AOI, ISO 9001 etc. ;

3. All the material we use have the RoHS identify;

4. All the components we use are the New & Original;

5. One-stop service can be provided from PCB design, 1-36 layers PCB manufacturing, components sourcing, PCB Assembly, to Fully Product Assembly.

![]()

PCB Assembly Application Field

Printed circuit boards And PCB Assembly are mainly used for many communication industry, medical equipments, consumer electronics ,automotive electronics , audio and video, optoelectronics, robotics, hydroelectric power, aerospace, education, power supply, printer ,Auto Industry ,Smart Home.etc.

![]()

Workshop

![]()

![]()

Common packaging

1.PCB: Vacuum packaging with carton box

2.PCBA: ESD packaging with carton box

![]()

Partner

![]()