-

High Light

Copper Automotive PCBA

,94v-0 Automotive PCBA

,Automotive PCB Fab And Assembly

-

Product NameAutomotive PCBA

-

LayersDouble Side ,Multilayer1-36layers

-

Copper Thickness0.3oz-6oz

-

Min. Line Spacing0.030mm/0.030mm

-

Board Thickness0.3.0.6.1.2 1.6 ......3.5mm

-

Min. Hole SizeLaser 0.05mm ; Mechnical 0.15

-

MaterialFR4 /Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI

-

Surface FinishingHASL,OSP,ENIG,HASL Lead Free,Immersion Gold

-

ServicePCB/PCBA/Circuit Board/SMT/DIP PCBA Layout And Design

-

PCB Boards TypeSingle-layer, Double-layer, Multi-layer, Rigid Board, Rigid-flexible Board, Flexible Board, High Frequency Board, HDI PCB Board, Aluminum Substrate Etc.

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A ,QC080000

-

Model NumberAutomotive PCBA

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

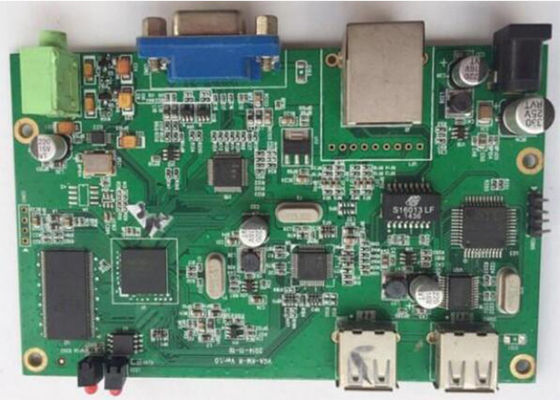

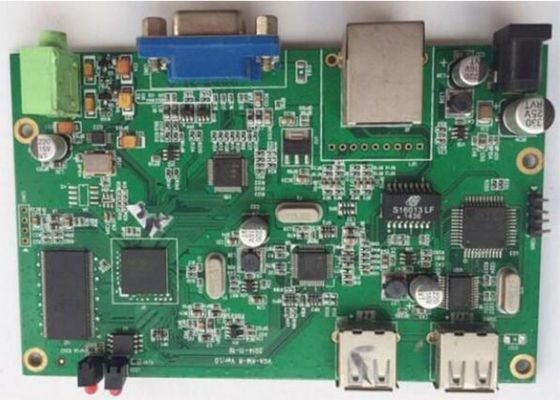

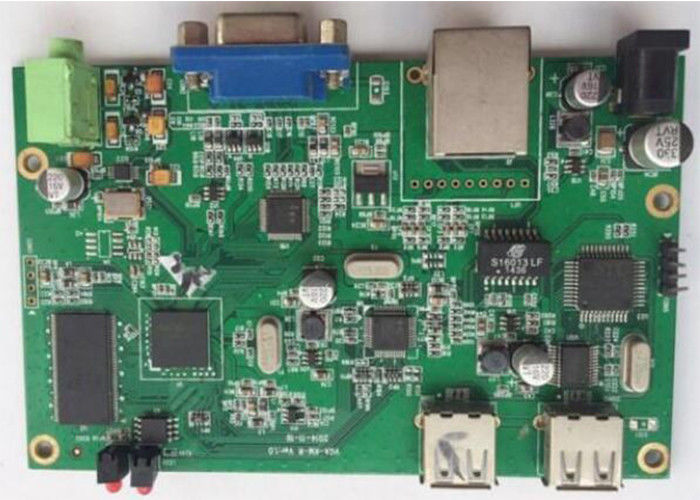

Copper Board Solder Mask 94v-0 Automotive PCBA 4 Layer 6 Layer

Copper Board Solder Mask 94v-0 4 Layer 6 Layers Multilayer Automotive PCBA

Automotive PCBA Introduction

Haina lean Electronics Co.,Ltdis a competitive China automotive driver circuit board prototype OEM manufacturer, supplier and vendor, you can get quick turn automotive driver circuit board prototype production prototypes and samples from our factory.

Factory Capabilities

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size | Laser 0.075mm | Laser 0.05mm |

| Mechnical 0.15mm | Mechnical 0.15mm | ||

| 5 | Min Line Width/Space | 0.035mm/0.035mm | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily Output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | ENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

PCBA CAPABILITIES

| PCBA Capability | |||

| Material Type | Item | Min | Max |

| PCB | Dimension (length,width,height.mm) | 50*40*0.38 | 600*400*4.2 |

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | ||

| Surface finish | HASL,OSP,Immersion gold,Flash Gold Finger | ||

| Components | Chip&IC | 1005 | 55mm |

| BGA Pitch | 0.3mm | - | |

| QFP Pitch | 0.3mm | - | |

PCB Assembly Craftsmanship

Our assembly process has been designed to meet all variations of PCBs, including single- or double-sided boards, Multilayer , rigid ,flexible circuits and Mixed technology. We run both leaded and RoHS/Lead-Free Surface Mount Technology (SMT) lines as well as wave solder equipment for both RoHS and leaded processes. Our manufacturing process allows for the highest quality product through process automation, environmental controls, automatic optical inspection (AOI) and flying probe at the best competitive price.

![]()

Our service

Electronic Manufacturing Service

PCB Electronic Design

PCB Layout Service

PCB Supplier & Quality Inspection Service

PCBA Components Sourcing

PCB Assembly process service

![]()

Delivery Time

| Prototype PCB | Batch | Prototype | Expedited |

| Double sides | 9 Days | 5 Days | 45h |

| Four-layer | 10 Days | 5 Days | 3 Days |

| Six-layer | 12 Days | 6 Days | 3 Days |

| Eight-layer | 12 Days | 7 Days | 4 Days |

| Ten-layer | 14 Days | 10 Days | 4Days |

| Twelve-layer | 14 Days | 10 Days | 5 Days |

| Fourteen-layer | 16 Days | 12Days | 6 Days |

| Sixteen-layer | 16 Days | 12 Days | 6 Days |

| Eighteen-layer | 18 Days | 14 Days | 6 Days |

| Twenty-layer | 18 Days | 14 Days | 10 Days |

| Twenty two-layer | 20 Days | 14 Days | 10 Days |

| Twenty four-layer | 20 Days | 14 Days | 10 Days |

| Twenty six-layer | 20 Days | 14 Days | 10 Days |

| Twenty eight-layer | 20 Days | 14 Days | 10 Days |

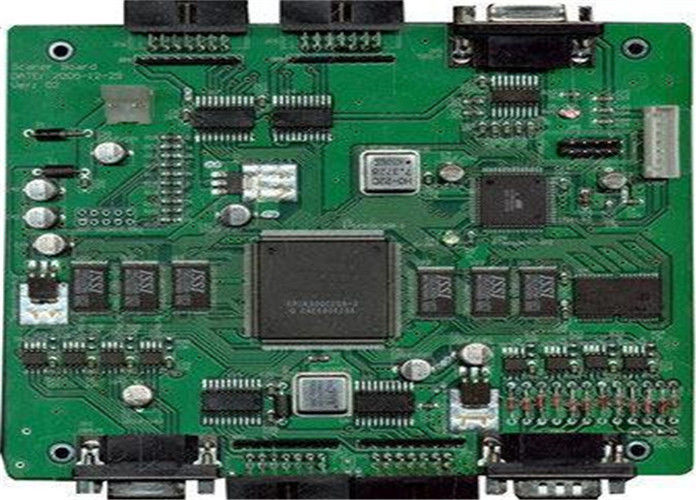

PCBA Application Field

Printed circuit boards And PCB Assembly are mainly used for many communication industry, medical equipments, consumer electronics ,automotive electronics , Elevator,audio and video, optoelectronics, robotics, hydroelectric power, Elevator,aerospace, education, power supply, printer ,Auto Industry ,Smart Home.etc.

![]()

Workshop

![]()

![]()

![]()

Testing service

Haina lean Electronics provides custom test service according to client's requirements and products.

Usually Haina lean Electronics Co.,Ltd PCBA Tech offers a full range of testing service. Including:

1. AOI(Automatic Optical Inspection)

2. Function Testing

3. In Circuit Testing

4. Testing Jig

5. Testing Service

6. X-Ray for BGA Testing

7. Printing Solder Paste Test

Each board is carefully examined by our dedicated inspection team using AOI and high magnification viewers.

Using our X-Ray machine, we test PCBs to component level and all wiring is fully inspected and tested.

Flash testing and earth bonding tests can also be undertaken where required.

Partners

![]()

Common packaging

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

![]()

Why choose us?

Welcome to visit our factory, Haina lean Electronics Co., Ltd.

1. Experienced: Focus on PCB And PCBA munufacturing over 10 years.

2. Professional: Expertise engineer with barrier-free English

3. Rapid delivery: On-time delivery rate reaches 98%

4.Cost effective: No excessive profits. Lower cost with same quality And service

FAQ

Q1.What are needed for quoation ?

PCB :Gerber File (Protel.Power PCB ,PADs File)

PCBA: Gerber File and BOM

Q2.What file formats do you accept for production ?

Gerber file :CAM350 RS274X

PCB File:protel 99SE ,P-CAD 2001 PCB

BOM:Excel (PDF,Word ,txt)

Q3.Are my files safe ?

Your files are held in complete safety and security ,we protect the intellectual property for our customers in the whole process .All documents from customer are never shared with any third parties .

Q4.What's your MOQ ?

No Moq ,We small orders as well as mass production

Q5.Shipping Cost ?

The shipping cost is determined by the destination ,weight ,packing size of the goods .We can provide shipping, air, land, express and other transportation services .

Q6.Can You provide fast rotating PCB ?

Yes , we can provide fast service 24 hours .

Q7.What are the services you can provide ?

One-stop contract manufacturing

A:PCB Assembly;

B:PCB Design & Layout

C:PCBA programming & functional testing;

D:Electronic components purchasing service;

E:Enclosure molding & final assembly with labels,instructions,enclosure, boxes.

Q8.Whether all PCBA s will be tested before delivery ?

Yes , we will test each piece of PCBA product under your testing methods ,to ensure quality and functionality .

Q9.Do you provide OEM service ?

Yes ,we offer PCB and PCBA OEM Service , we manufacture the PCB and PCBA products to your design and requirements .

Company Information

Beijing Haina lean Electronics Co.,Ltd is one of the most professional PCB manufacture in Beijing,China. With more then 10 years of development, Haina Lean Electronics turns into a first class manufacture of HDI PCB ,with production capability 4000 square meters.

Our factory is providing high quality bare PCB, PCB layout design service and PCB assembly service,including components sourcing, function test,conformal coating and complete assembly for clients all.

We have profuse experience in manufacturing PCB,owned experienced technical R & D technology team, young and professional sales and customer service team, experienced and professional procurement team and assembly testing team, which make sure the products quality of the pass rate, on-time delivery rate of customer orders.

Our services include: circuit board design and layout, 2-46 layers PCB manufacturing, professional FPC production, electronic components purchasing, SMT professional processing, Soldering and Assembly, especially sample and small bulk orders. we have the advantages of a quick quote, fast production, fast delivery.

The company pursues "inclusiveness, excellence, people-oriented". Constantly innovate, take technology as the core, regard quality as life, and wholeheartedly provide customers with high-quality and high-efficiency humanized services.We are willing to serve our customers with the principle of continuous honesty & trustworthiness, pragmatism and innovation.

Our customers are from over more than 80 countries. At present, the main cooperation industries are automotive electronics, communications, audio and video, optoelectronics, robotics, hydroelectric power, medical care, aerospace, education, radio frequency, power supply, printer etc industries.

![]()