Blood Pressure Monitor 1oz Medical PCB Assembly , SMT FR-4 ENIG HDI PCB Assembly

-

High Light

1.6mm Medical PCB Assembly

,1oz Medical PCB Assembly

,ENIG HDI PCB Assembly

-

Product NameMedical PCB Assembly

-

LayersDouble Side ,Multilayer

-

Copper Thickness0.3oz 1oz 2oz 3oz ... 6oz

-

Min. Line Spacing0.030mm / 0.030mm

-

Board Thickness0.3mm 1.2nn 1.6mm 2.0mm ......3.5mm

-

Min. Hole SizeLaser 0.05mm ; Mechnical 0.15

-

Surface TreatmentHASL,OSP,ENIG,HASL Lead Free,Immersion Gold

-

MaterialFR-4,High Tg FR-4, Halogen Free FR-4, Thick Copper FR-4, Aluminium Based, Rogers, Taconic

-

ApplicationMedical Equipments, Consumer Electronics ,automotive Electronics Etc.

-

Solder Mask ColorGreen,white,black,red,orange,yellow,blue,purple

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A ,QC080000

-

Model NumberMedical PCB Assembly

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

Blood Pressure Monitor 1oz Medical PCB Assembly , SMT FR-4 ENIG HDI PCB Assembly

SMT FR-4 Blood Pressure Monitor ENIG HDI Medical PCB Assembly

Medical PCB Assembly Introduction

Haina Lean offers first-class Medical PCB Assembly solutions for the medical device market, specializing in high-mix with large flexibility technology. we have R&D experts to design and develop PCB assembly of the highest quality for critical medical devices.

With capabilities from multi-layered to flexible printed circuit boards, we'll be your good partner for printed circuit board design, componients sourcing, pcb assembly, and testing. From design to delivery, we provide our customers with exceptional PCBA solutions and services worldwide.

Factory Capacity

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size |

Laser 0.075mm Mechnical 0.15 |

Laser 0.05mm Mechnical 0.15 |

| 5 | Min Line Width/Space | 0.035mm/0.035 | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | HASL Lead Free /ENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

PCBA CAPABILITIES

| PCBA Capability | |||

| Material Type | Item | Min | Max |

| PCB | Dimension (length,width,height.mm) | 50*40*0.38 | 600*400*4.2 |

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | ||

| Surface finish | HASL,OSP,Immersion gold,Flash Gold Finger | ||

| Components | Chip&IC | 1005 | 55mm |

| BGA Pitch | 0.3mm | - | |

| QFP Pitch | 0.3mm | - | |

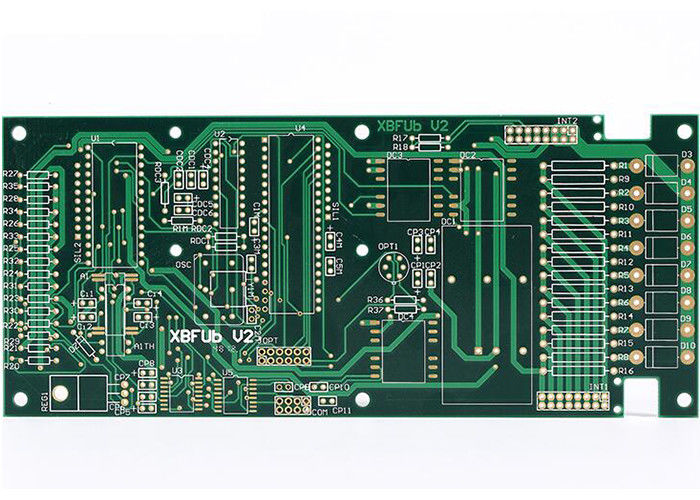

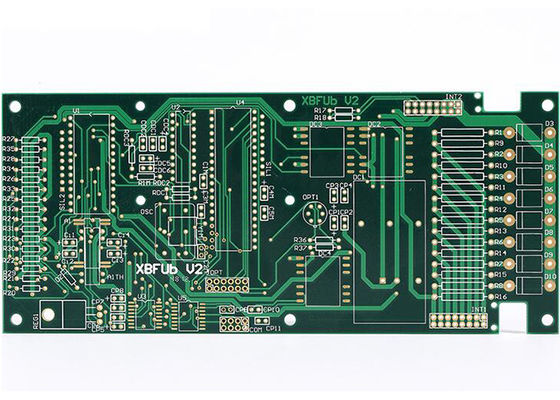

Medical PCB Assembly Technologies

Multi-layer / High Density Interconnect (HDI) PCBs ;

THT (Through-Hole Technology );

Flex & Rigid-Flex ;

SMT & mini SMT ;

BGA techonology ;

Reflow Soldering ;

Wave-soldering ;

Conformal Coating ;

etc.

Our service

1.PCB Design & Layout 2.PCB Prototyping 3.PCB Fabrication 4.Turn Prototype PCB Assembly

5.PCB Assembly Service 6.Contract PCB Assembly 7.Trunkey PCB Assembly 8.Components sourcing,

9.Function test 10.conformal coating 11.complete assembly

![]()

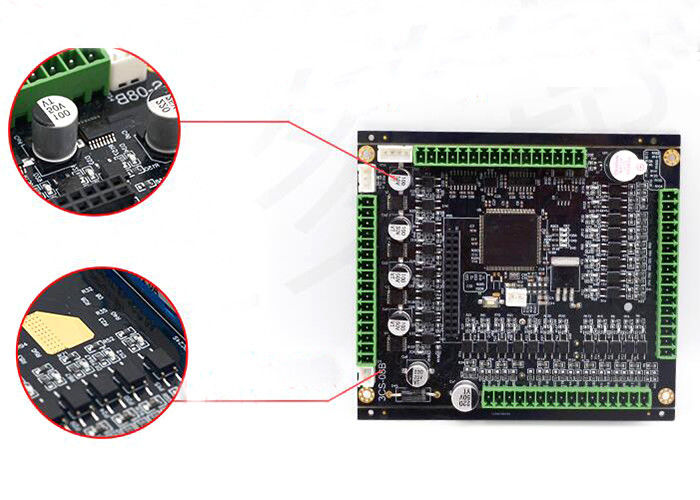

Workshop & Equipment

Our assembly process has been designed to meet all variations of PCBs, including single- or double-sided boards, Multilayer , rigid ,flexible circuits and Mixed technology. We run both leaded and RoHS/Lead-Free Surface Mount Technology (SMT) lines as well as wave solder equipment for both RoHS and leaded processes. Our manufacturing process allows for the highest quality product through process automation, environmental controls, automatic optical inspection (AOI) and flying probe at the best competitive price.

![]()

![]()

![]()

PCB Assembly Application

Printed circuit boards And PCB Assembly are mainly used for many communication industry, medical equipments, consumer electronics ,automotive electronics , audio and video, optoelectronics, robotics, hydroelectric power, aerospace, education, power supply, printer ,Auto Industry ,Smart Home.etc.

![]()

Delivery Time

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

FAQ

Q1: What service do you have?

A1: We provide turnkey solution including RD, PCB fabrication, SMT, final assembly ,testing and other

value-added service.

Q2: What are the main products of your PCB/PCBA services?

A2: Our PCB/PCBA services are mainly for the industries including Medical, Automotive, Energy,

Metering/Measurements, Consumer Electronics.

Q3: Can we inspect quality during production?

A3: Yes, we are open and transparent on each production process with nothing to hide. We welcome customer

inspect our production process and check in house

Q4: How can we ensure our information should not let third party to see our design?

A4: We can sign NDA effect by customer side local law and promising to keep customers data in high

confidential level.

Q5: What does customer need for a customized PCB order?

A5: When you place a PCB order, the customers need to provide Gerber or pcb file. If you do not have the file in

the correct fomat, you can send all the details related to the products.

Q7: Does you have an minimum order quantity?

A7: We accept order with as low as a quantity of 1 (piece or panel).

Q8:what is the difference between PCB, PCBA and FPC?

A8: PCB is bare board without any components.

PCBA is the PCB through SMT or plug-in processing, welding assembly on the PCB board required electronic components, such as IC, resistor, capacitor, crystal oscillator, transformer and other electronic components, after reflow oven high temperature heating, will form the mechanical connection between components and PCB board, thus forming PCBA.

FPC generally uses Pi as base material, which is flexible and can be bent and flexed at will .