-

High Light

THT Prototype PCB Assembly

,Electronic Prototype PCB Assembly

,Lead Free Electronic PCBA

-

Product NameFR-4 HASL Lead Free Prototype Pcb Assembly Electronic Board Assembly

-

MaterialFr-4, Halogen Free

-

Copper Thickness1/3oz To 6oz

-

Max Board Size700x610mm

-

Min. Line Spacing0.030mm

-

Min. Line Width0.03mm

-

Board Thickness0.3-3.5mm

-

Surface FinishingHASL,OSP,ENIG,HASL Lead Free,Immersion Gold

-

Min. Hole Size0.07--2.0 Mm,0.075mm(3mil)

-

UsageOEM Electronics

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A ,QC080000

-

Model NumberPCB Assembly 02

-

Minimum Order Quantity1PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

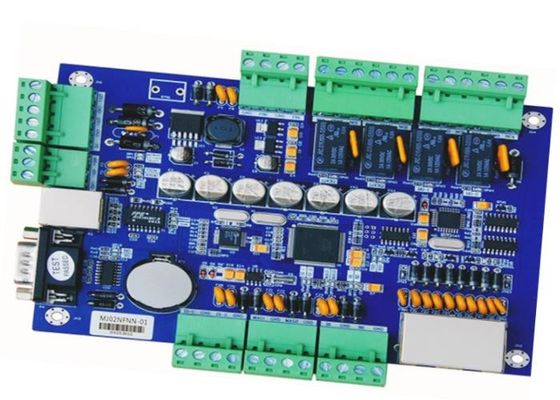

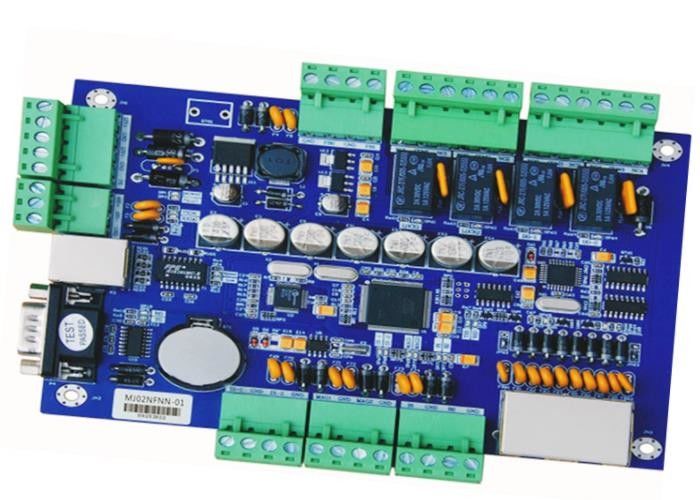

THT FR-4 HASL Lead Free Electronic Prototype PCB Assembly

FR-4 HASL Lead Free prototype pcb assembly Electronic Board Assembly

Electronic Board Assembly Introduction

PCB assembly or PCBA for short is a PCB with components mounted on is called an assembled PCB, and the manufacturing process.

An advanced circuit board won't be able to give its functionality until components are mounted on it.

The simplicity of the blank PCB gives plenty of freedom for engineers and designers to add components as needed.

This blank slate provides flexibility and makes the bare PCB boards viable for mass production instead of making them unique for each order.

These PCB boards require more design work than other wiring methods, but the assembly and manufacturing tend to be automated afterward. The automation makes PCB boards the cheapest and most efficient option.

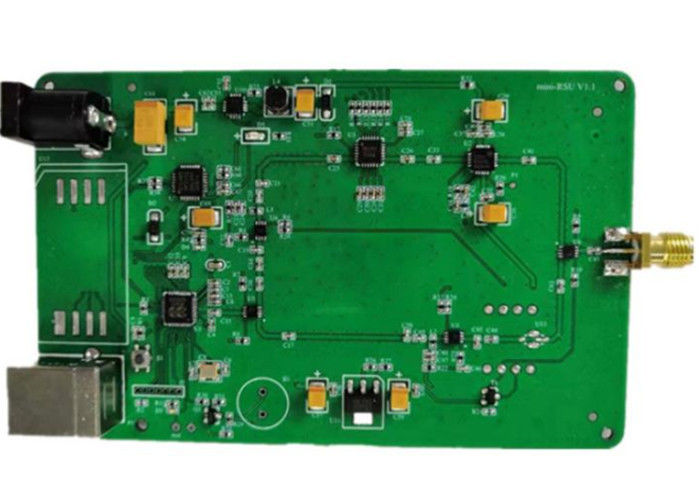

Our engineers is qualified and experienced in producing surface-mount (SMT), through-hole (THT) and mixed-technology components and fine-pitch parts and ball grid arrays (BGAs) for high-density FR-4 PCBs .

Max layer count: 36L

Beijing Haina Lean Electronic, as Printed Circuit Board manufacturing & Assembly Leader, is a full service electronic manufacturing company.

We offer exclusive services to help our customers with their PCB Projects.

When you partner with us, we do everything possible to make sure your assemblies are completed on-time to your specifications with the highest quality.

We truly consider ourselves an extension of your company's team.

PCB CAPABILITIES

|

Base material

|

FR4,High-TG FR4,CEM3,aluminum, High Frequencey frequency(Rogers,Taconic,Aron,PTFE,F4B)

|

|

Layers

|

1-4 Layers(Alunimum), 1-32 layers(FR4)

|

|

Copper Thickness

|

0.5oz, 1oz, 2oz, 3oz,4oz

|

|

Dielectric Thickness

|

0.05mm, 0.075mm, 0.1mm,0.15mm,0.2mm

|

|

board Core Thickness

|

0.4mm,0.6mm, 0.8mm, 1.0mm, 1.2mm,

|

| 1.5mm, 2.0mm, 3.0mm and 3.2mm | |

|

Board Thickness

|

0.4mm - 4.0mm

|

|

Thickness Tolerance

|

+/-10%

|

|

Aluminum Machining

|

Drilling, Tapping, Milling, Routing, Die-Punching,

|

| Break-off tab available | |

|

Min Hole

|

0.2 mm

|

|

Min Track Width

|

0.2mm (8mil)

|

|

Min Track Gap

|

0.2mm (8mil)

|

|

Min SMD Pad Pitch

|

0.2mm (8mil)

|

|

Surface Finishing

|

HASL lead free,ENIG,Plated Gold,Immersion Gold,OSP

|

|

Solder Mask Color

|

Green, Blue, Black, White, Yellow, Red, Matt Green, Matt Black, Matt Blue

|

|

Legend Color

|

Black, White etc

|

|

Assembly Types

|

Surface mount

|

| Thro-hole | |

| Mixed technology (SMT & Thru-hole) | |

| Single or double sided placement | |

| Conformal coating | |

| Shield cover assembly for EMI emission control | |

|

Parts Procurement

|

Full Turnkey

|

| Partial Turnkey | |

| Kitted/Consigned | |

|

Component types

|

SMT 01005 or larger

|

| BGA 0.4mm pitch, POP (Package on Package) | |

| WLCSP 0.35mm pitch | |

| Hard metric connectors | |

| Cable & wire | |

|

SMT Parts Presentation

|

Bulk

|

| Cut tape | |

| Partial reel | |

| Reel | |

| Tube | |

| Tray | |

|

Stencils

|

Laser-cut stainless steel

|

|

Other Techniques

|

Free DFM Review

|

| Box Build Assembly | |

| 100% AOI test and X-ray test for BGA | |

| IC programming | |

| Components cost-down | |

| Function test as custom | |

| Protection technology |

Our SMT capabilities:

SMT Assembly: SMT provides a flexible high technology.

These solutions include:

7 high-speed placement machines, 7 automatic printers with fiducial alignment, 2 X-ray machines, BGA maintenance machines, ICT test machines

Our DIP function:

A-8 semi-assembly production line with four wave soldering machines

1 U-shaped automatic assembly line for box-type building products with test stations

High temperature / low temperature aging test furnace B-4 for products required for aging test

With time control and temperature control

All products are 100% inspected and tested during the DIP process

Haina lean Electronics Co.,Ltd is a competitive China customize pcba for medical breathing machine OEM manufacturer, supplier and vendor, you can get quick turn customize pcba for medical breathing machine production prototypes and samples from our factory.

Hot Tags: customize pcba for medical breathing machine, China, supplier, manufacturer, factory, OEM manufacturer, vendor, samples, production, prototypes, quick turn.

Electronic Board Assembly Process

1.Solder Paste stenciling

2.Surface Mount Technology (Pick and Place)

3.Reflow Soldering

4.Inspection and Quality Control

5.Through-Hole Component Insertion (DIP Process)

6.Final Inspection and Functional Test

![]()

Why choose us?

Reliable PCB Manufacturing & Assembly; Quality PCB Fabrication; Best On Time PCB Shipping Record; Financially Stable PCB Company; 24 Hour Tech Support; PCB Instant Quoting; Easy PCB Order Status Tracking; No Minimum PCB Order Requirements; Waived Tooling Charges; Free PCB Design Software & Free File Check.

Our advantage

Service value:

Independent quotation system to quickly serve the market

PCB manufacturing:

High-tech PCB and PCB assembly production line

Material purchasing:

A team of experienced electronic component procurement engineers

SMT post soldering:

Dust-free workshop, high-end SMT patch processing

![]()

![]()

Delivery Time

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Electronic Board Assembly Application Field

Our products are widely used in communication equipment, industrial control, consumer electronics, medical equipment, aerospace, light-emitting diode lighting, automotive electronics.

![]()

Workshop

![]()

![]()

Partners

![]()

Common packaging

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

![]()

Certification

![]()

FAQ

FAQ

1.What are needed for quotation?

PCB: Quantity, Gerber file and Technic requirements(material,surface finish treatment, copper thickness,board thickness ......)

PCBA: PCB information, BOM, (Testing documents...)

2. What file formats do you accept for production?

Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

3.Are my files safe?

Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole process.. All documents from customers are never shared with any third party.

4.MOQ?

There is no MOQ .We can flexibly handle small and mass production.

5.Shipping Cost ?

The shipping cost is determined by the destination ,weight ,packing size of the goods .We can provide shipping, air, land, express and other transportation services .

6.How to ensure high-quality production?

The process is strictly controlled under ISO 9001:2015 standards.

Most of our advanced equipment and tools are imported from abroad. Such as Flying Probe, X-ray Inspection, AOI (Automated Optical Inspector) and ICT (in-circuit testing).

We have a very professional QC team.

Q7.What are the services you can provide ?

One-stop contract manufacturing

A:PCB Assembly;

B:PCB Design & Layout

C:PCBA programming & functional testing;

D:Electronic components purchasing service;

E:Enclosure molding & final assembly with labels,instructions,enclosure, boxes.

Q8.Whether all PCBA s will be tested before delivery ?

Yes , we will test each piece of PCBA product under your testing methods ,to ensure quality and functionality .

Q9.Do you provide OEM service ?

Yes ,we offer PCB and PCBA OEM Service , we manufacture the PCB and PCBA products to your design and requirements .

Company Information

Haina lean Electronics Co., Ltd is a one-stop EMS supplier integrating PCB design, PCB manufacturing, Component sourcing and PCB assembly.

Our company was established in May 1, 2006 in Beijing. And expansion was completed in June 2016. The company is specialized in electronic products supporting processing services, mainly to undertake circuit board design, layout production, components procurement, PCB plate making, circuit board welding assembly debugging and other OEM/ODM services.

Our first factory is located in Changping District, Beijing, the main radiation Haidian, Changping, Chaoyang three areas of Beijing. Since our company’s establishment, we have been adhering to creating high quality, high efficiency, low-cost business philosophy based on the circuit board processing industry for customers. Most of the key staff of the company are mature technical talents who have been engaged in the industry for more than 10 years, and have rich experience in the production of SMT and DIP, also has rich experience in production for high density & difficulty to package components such as BGA. We obtain a good reputation in the industry through the continuous efforts from all staff and high quality service . Our second branch plant is located in Langfang city, and mainly cover Fengtai and Daxing Yizhuang area. Our factory covers an area of 6000 square meters.

Our company pursues "inclusiveness, excellence, people-oriented". Constantly innovate, take technology as the core, regard quality as life, and wholeheartedly provide customers with high-quality and high-efficiency humanized services.We are willing to serve our customers with the principle of continuous honesty & trustworthiness, pragmatism and innovation.

At present, the main cooperation industries are automotive electronics, communications, audio and video, optoelectronics, robotics, hydroelectric power, medical care, aerospace, education, radio frequency, power supply, printer etc industries.

![]()