-

High Light

ROHS PCBA Prototype

,FR4 PCBA Prototype

,1.0mm PCB prototype and assembly

-

Product NamePCB Board Assembly

-

Copper Thickness0.3. 0.56 ..... 6oz

-

Layers1-36 Layers

-

Max Board Size700x610mm

-

Min. Line Spacing0.030mm

-

Board Thickness0.3mm 1.0mm 1.2mm 1.6mm ...... 3.5mm

-

MaterialFR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI

-

Surface FinishingHASL,OSP,ENIG,HASL Lead Free,Immersion Gold

-

Solder Mask ColorBlue.green.red.black.white.etc

-

Pcb Assembly MethodMixed,BGA,SMT,Through-hole

-

Place of OriginCHINA

-

Brand NameHNL-PCBA

-

CertificationISO9001,IS16949, ISO14001,ROHS ,IPC-A ,QC080000

-

Model NumberPCB Assembly

-

Minimum Order Quantity1 PC

-

PriceNegotiable

-

Packaging DetailsESD packaging with carton box

-

Delivery Time1-7days

-

Payment TermsT/T, Western Union, L/C, MoneyGram

-

Supply Ability10,000,000 Point /Day

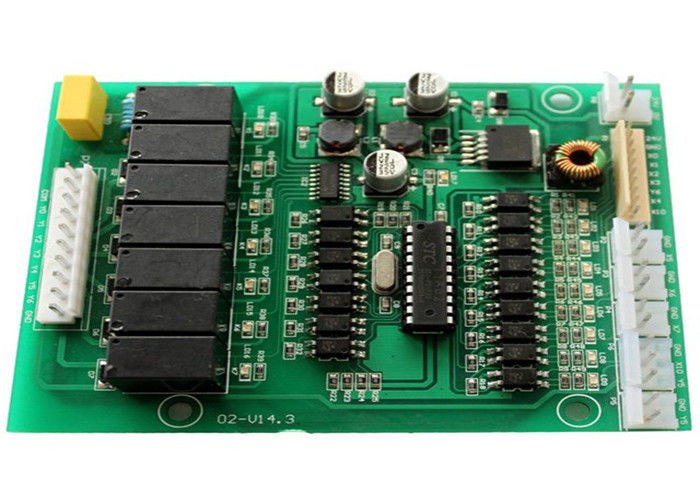

Hot Air Solder Levelling Green Solder Mask FR4 PCBA Prototype

Hot air solder levelling Green solder mask FR4 PCB board assembly

PCB board assembly Introduction

Haina Lean provide One stop turnkey PCB services, Including PCB manufacturing, PCB assembling, PCBA components sourcing and PCBA function testing.

PCB board assembly is a finished board. it is divided into 4 layers, 6 layers 8 lavers and other multilayer , and the most common are 4 laver and 6 laver PCBs.

PCB'A is the circuit board plug-in assembly, added SMT , DIP process ,Mix technology. (PCBA=Printed Circuit Board +Assembly)

In other words, the PCB board goes through the SMT and then goes through the entire process of the DIP plug-in, abbreviated as PCBA.

PCB CAPABILITIES

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size |

Laser 0.075mm Mechnical 0.15 |

Laser 0.05mm Mechnical 0.15 |

| 5 | Min Line Width/Space | 0.035mm/0.035 | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | HASL Lead Free /ENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

PCBA CAPABILITIES

| PCBA Capability | |||

| Material Type | Item | Min | Max |

| PCB | Dimension (length,width,height.mm) | 50*40*0.38 | 600*400*4.2 |

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | ||

| Surface finish | HASL,OSP,Immersion gold,Flash Gold Finger | ||

| Components | Chip&IC | 1005 | 55mm |

| BGA Pitch | 0.3mm | - | |

| QFP Pitch | 0.3mm | - | |

PCBA Assembly Process

PCB Loading , Solder paste printing ,surface mounting , Reflow soldering , DIP Soldering ,Wave soldering ,AOI ,X ray ,First article inspection ,QC ,Package ,Shipping .

![]()

Our workshop

![]()

![]()

Our services include

PCB Design

PCB Fabrication

PCBA Assembly

Components Sourcing

Function Testing

Enclosure/box/finished Assembly

![]()

Delivery Time

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

PCB Board Assembly Application Field

Medical Products ,Office Equipment,Household Appliances,Automotive electronics, digital electronics,

aerospace products, communication electronics, industrial control, elevator, high speed railway, digital TV,

satellite, radar,Video processing, Gateway control ,Network devices ,etc

![]()

Partners

![]()

Common packaging

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

![]()

Certification

![]()

FAQ

Q1.What are needed for quoation ?

PCB :Gerber File (Protel.Power PCB ,PADs File)

PCBA: Gerber File and BOM

Q2.What file formats do you accept for production ?

Gerber file :CAM350 RS274X

PCB File:protel 99SE ,P-CAD 2001 PCB

BOM:Excel (PDF,Word ,txt)

Q3.Are my files safe ?

Your files are held in complete safety and security ,we protect the intellectual property for our customers in the whole process .All documents from customer are never shared with any third parties .

Q4.What's your MOQ ?

No Moq ,We accept small orders as well as mass production

Q5.Shipping Cost ?

The shipping cost is determined by the destination ,weight ,packing size of the goods .We can provide shipping, air, land, express and other transportation services .

Q6.Can You provide fast rotating PCB ?

Yes , we can provide fast service 24 hours .

Q7.What are the services you can provide ?

One-stop contract manufacturing

A:PCB Assembly;

B:PCB Design & Layout

C:PCBA programming & functional testing;

D:Electronic components purchasing service;

E:Enclosure molding & final assembly with labels,instructions,enclosure, boxes.

Q8.Whether all PCBA s will be tested before delivery ?

Yes , we will test each piece of PCBA product under your testing methods ,to ensure quality and functionality .

Q9.Do you provide OEM service ?

Yes ,we offer PCB and PCBA OEM Service , we manufacture the PCB and PCBA products to your design and requirements .

Company Information

Haina lean Electronics Co., Ltd is a one-stop EMS supplier integrating PCB design, PCB manufacturing, Component sourcing and PCB assembly.

Our company was established in May 1, 2012 in Beijing. And expansion was completed in June 2016. The company is specialized in electronic products supporting processing services, mainly to undertake circuit board design, layout production, components procurement, PCB plate making, circuit board welding assembly debugging and other OEM/ODM services.

Our first factory is located in Changping District, Beijing, the main radiation Haidian, Changping, Chaoyang three areas of Beijing. Since our company’s establishment, we have been adhering to creating high quality, high efficiency, low-cost business philosophy based on the circuit board processing industry for customers. Most of the key staff of the company are mature technical talents who have been engaged in the industry for more than 10 years, and have rich experience in the production of SMT and DIP, also has rich experience in production for high density & difficulty to package components such as BGA. The factory covers an area of 4000 square meters. Since its establishment, we obtain a good reputation in the industry through the continuous efforts of all staff and high quality service . Our second branch plant is located in Langfang city, and mainly cover Fengtai and Daxing Yizhuang area.

![]()